As steam enters the first stage turbine, it embarks on a journey through a meticulously engineered system, where its thermodynamic properties and flow characteristics dictate the turbine’s performance and efficiency. This discourse delves into the intricacies of steam’s behavior within the turbine, exploring its impact on blade design, flow dynamics, and overall system performance.

The first stage turbine, acting as the initial point of energy conversion, plays a pivotal role in determining the efficiency of the entire turbine system. Understanding the thermodynamic properties of steam entering this stage is crucial for optimizing turbine design and operation.

Steam Properties

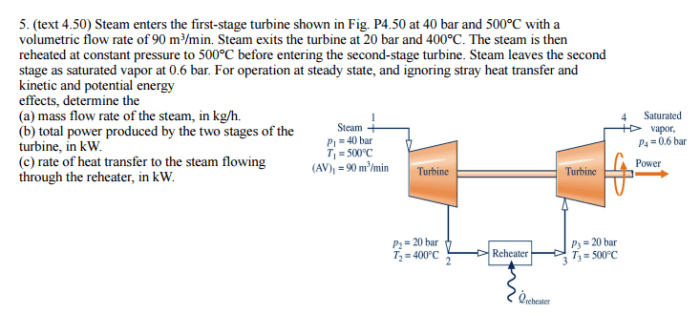

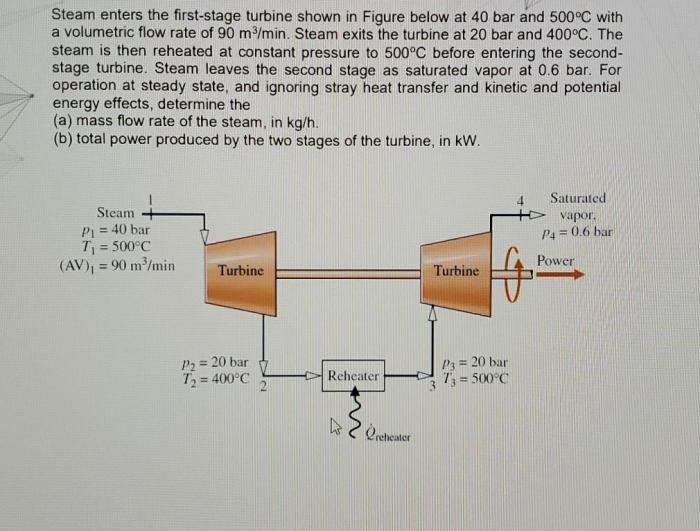

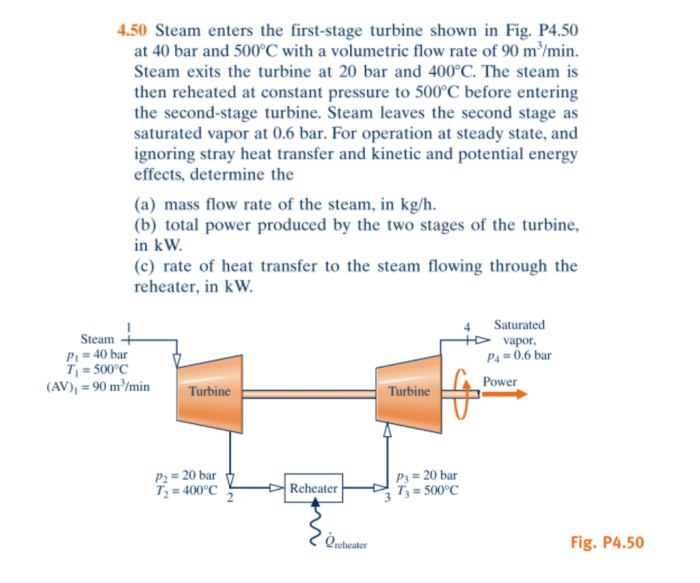

Steam entering the first stage turbine possesses unique thermodynamic properties that significantly influence turbine performance. Enthalpy, pressure, and temperature are the primary properties that characterize steam at the turbine inlet. The table below compares these properties at the turbine inlet and outlet:

| Property | Turbine Inlet | Turbine Outlet |

|---|---|---|

| Enthalpy (kJ/kg) | h1 | h2 |

| Pressure (kPa) | P1 | P2 |

| Temperature (°C) | T1 | T2 |

Steam quality, defined as the ratio of vapor mass to total mass, also plays a crucial role in turbine performance. Higher steam quality indicates a higher proportion of vapor, resulting in increased efficiency and specific work output.

Turbine Design

The design of the first stage turbine blades is crucial for efficient steam utilization. The blade shape and geometry influence the flow of steam and the efficiency of energy conversion. The blades are typically designed with:

- Airfoil profiles to optimize steam flow and reduce pressure losses.

- Twisted and tapered shapes to accommodate varying steam velocities and pressures.

- Curved leading edges to minimize shock losses and improve flow transition.

Turbine blades are constructed using materials with high strength, corrosion resistance, and thermal stability, such as:

- Stainless steel

- Nickel-based alloys

- Titanium alloys

Steam Flow Analysis

Analyzing the flow of steam through the first stage turbine is essential for understanding turbine performance. The steam path can be illustrated using a diagram, showing the pressure drop and velocity changes as steam passes through the blades. The steam velocity and pressure affect the turbine efficiency as follows:

- Higher steam velocity increases kinetic energy and efficiency.

- Lower steam pressure reduces expansion work and efficiency.

Turbine Performance

The performance of the first stage turbine can be evaluated based on its efficiency and specific work output. Turbine efficiency is defined as the ratio of actual work output to the isentropic work output. Specific work output is the work produced per unit mass of steam flowing through the turbine.

Factors that affect turbine performance include:

- Steam pressure

- Steam temperature

- Steam flow rate

- Blade design

Control and Monitoring, Steam enters the first stage turbine

Proper control and monitoring systems are essential for maintaining turbine safety and efficiency. Control systems regulate steam flow and turbine speed, while instrumentation monitors turbine performance parameters such as pressure, temperature, and vibration.

Effective control and monitoring enable:

- Optimization of steam flow for maximum efficiency.

- Prevention of overspeed or underload conditions.

- Early detection of potential problems and timely maintenance.

FAQ Corner: Steam Enters The First Stage Turbine

What are the key thermodynamic properties of steam entering the first stage turbine?

The enthalpy, pressure, and temperature of steam at the turbine inlet are critical thermodynamic properties that influence turbine performance.

How does steam quality affect turbine performance?

Steam quality, represented by its dryness fraction, directly impacts turbine efficiency. Higher steam quality leads to improved efficiency.

What are the key design considerations for first stage turbine blades?

Blade shape, geometry, and material properties play a crucial role in optimizing steam flow and efficiency within the first stage turbine.